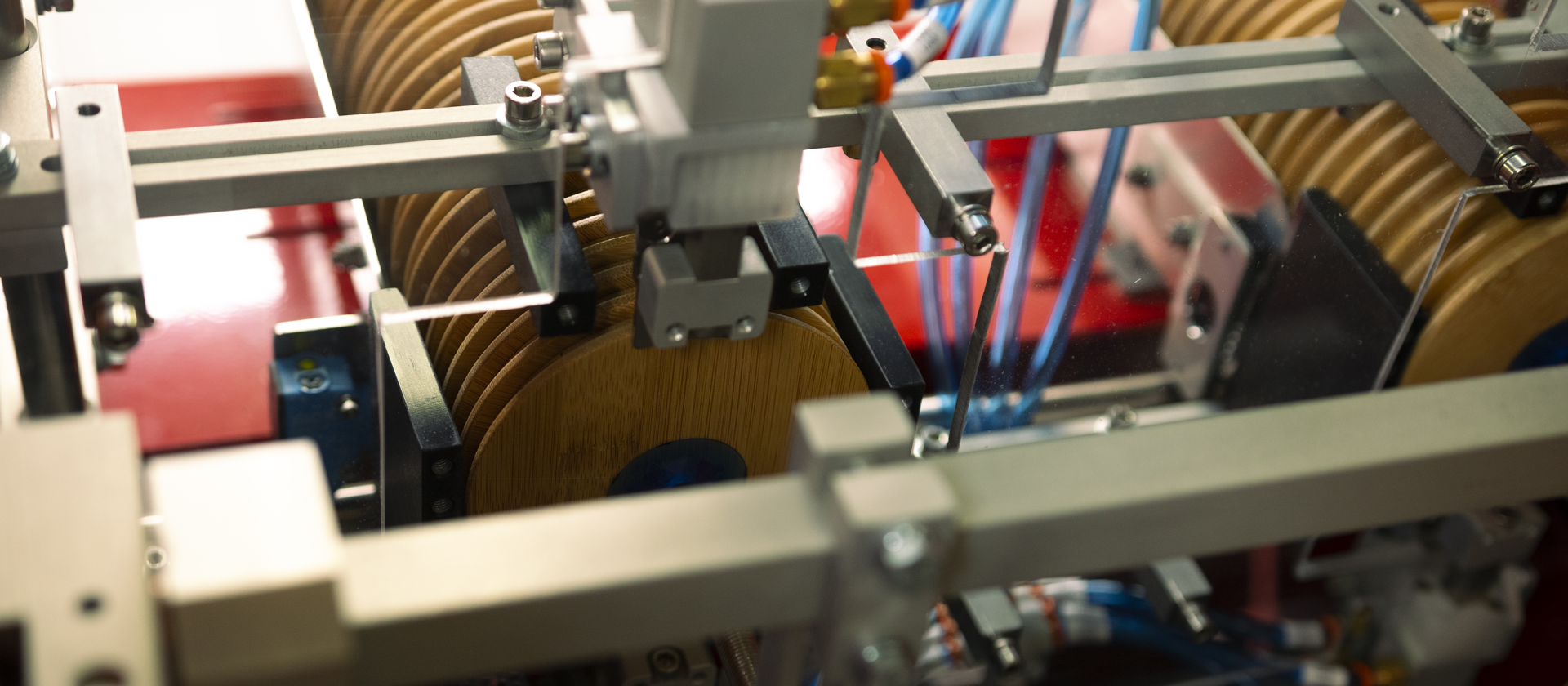

MGS creates next generation IPP 2.0

Building on more than 40 years of product handling expertise, MGS creates the next generation of its trusted Intermittent Pick n’ Place machines. Read on to see why you should choose the IPP 2.0.

Speed

Denesting at speeds of up to 75 cycles per minute, the IPP 2.0 is 25% faster than previous models. Operators can perform changeovers in under 3 minutes with our Kwik Klips™ or Clamp and Release quick-change tooling that minimize downtime and boost operational flexibility.

Flexibility

Quick-change tooling means the machine can handle a wide range of products. Clipping is factory-set for your specific product, so there’s no need for fine-tuning. This results in unlimited flexibility while the 30” magazine is suitable for a large product capacity.

Precision

The IPP 2.0 creates steady, precise product placement - especially at higher speeds, thanks to smooth pivot rod motion. Missed pick detection technology prevents malfunctions and product waste, increasing uptime and ROI.

Ease of Use

With a small footprint and clean control panel design, the IPP 2.0 can be installed anywhere and is easy to operate. The easy-to-access control panel can be configured to a left- or right-hand orientation and can even be converted in field. The height adjust mechanism supports easy installation and product changeover.

Quick Delivery

Building on our proven Pick n' Place technologies, the IPP 2.0 features a streamlined design that accommodates a majority of Pick n' Place applications. Automate the feeding of trays, lids, paper, labels, multi-fold coupons, and much more with a fast 5-week lead time and a simple 1-day installation. Get up and running quickly with the IPP 2.0 and maximize production output.

See the IPP 2.0 in action:

Interested in the IPP 2.0? Reach out to us to discuss your project today!