Innovation

We pride ourselves in being forward thinking and innovative - we turn our ideas into solutions, introucing new products and services that create value for our customers.

We pride ourselves in being forward thinking and innovative - we turn our ideas into solutions, introucing new products and services that create value for our customers.

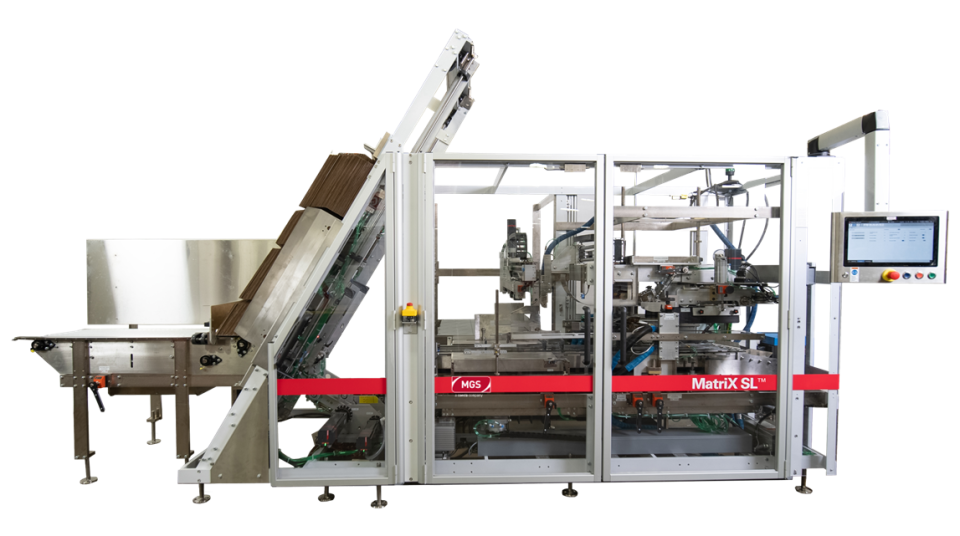

The MatriX SL™ is a compact, side-load case packer designed to adapt to your production needs. With the ability to handle three case styles, regular slotted containers, wrap arounds, and trays, all on a single platform, it eliminates the need for multiple machines and streamlines your packaging process from the ground up.

Learn more about the MatriX SL™.

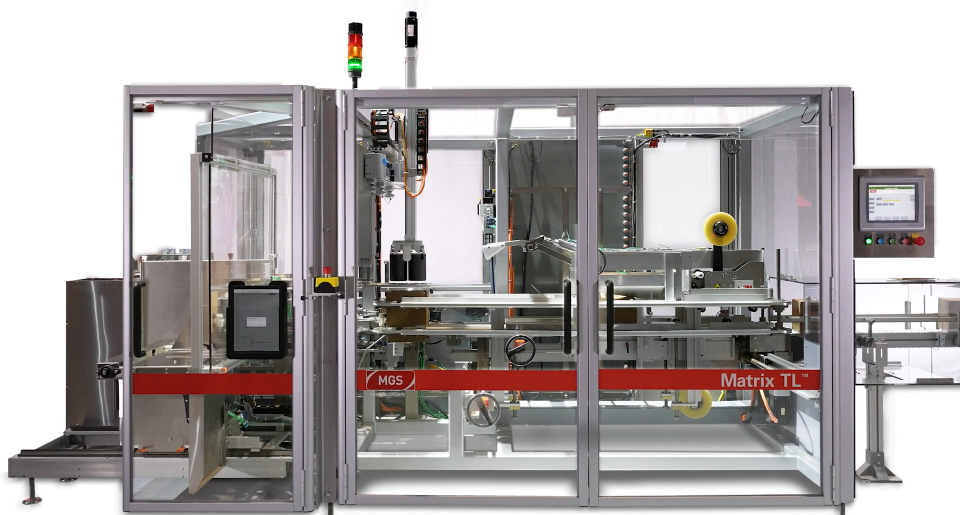

Download and readThe Matrix TL is a COMPLETE case packing system with erect, load, and seal contained in one module. With speeds up to 20 cases per minute, it has one of the fastest rate per footprint ratios in the market. Built with a small footprint of just over four meters long, this machine is compact enough to fit into virtually any type of configuration in your facility.

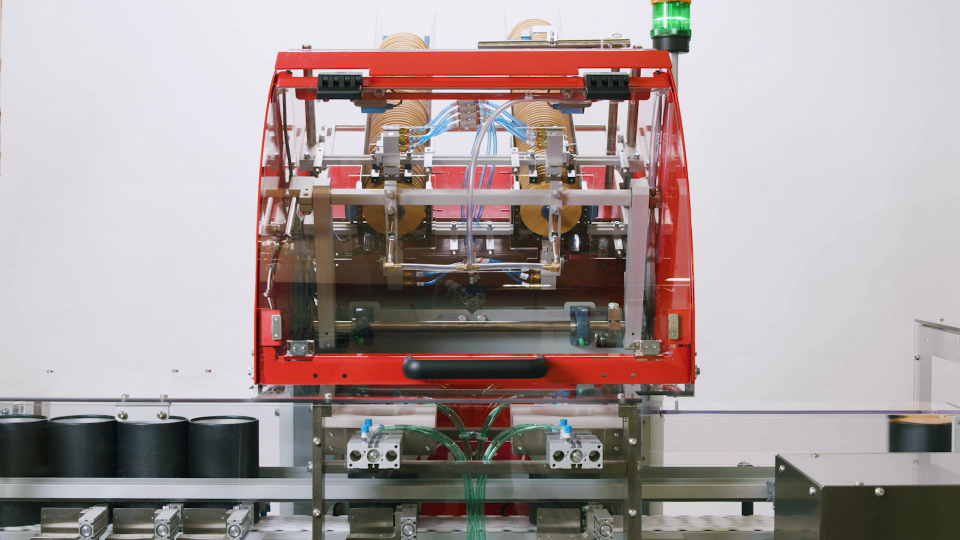

Building on more than 40 years of product handling expertise, MGS created the next generation of its trusted Intermittent Pick n’ Place machines, the IPP 2.0.

Choosing MGS IPP 2.0 has many benefits inching a small footprint and clean control panel design. The IPP 2.0 can be installed anywhere and is easy to operate. The easy-to-access control panel can be configured to a left- or right-hand orientation and can even be converted in field. The height adjust mechanism supports easy installation and product changeover.

Looking for a quick delivery? The IPP 2.0 pick and place can be in production in less than 6 weeks!

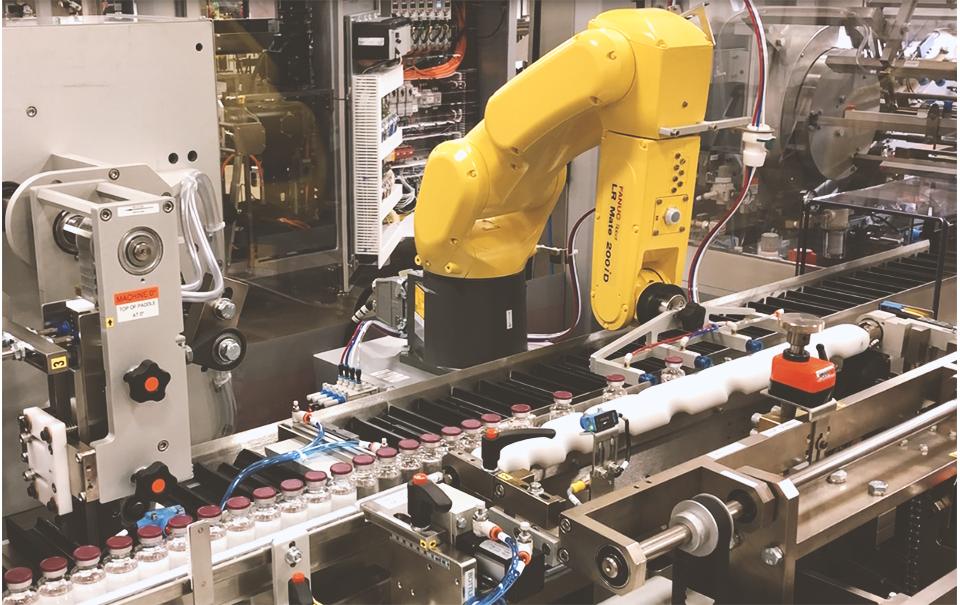

Innovative methodologies for handing incoming product is the cornerstone to successful end-of-line packaging projects. At MGS, we develop, design and manufacture a complete line of product handling solutions to complement and enhance our entire line portfolio. Our capabilities include:

• High speed infeeds

• High speed singulation

• Bulk to singulation and orientation

• Intermittent and continuous motion arrangement

• Accurate arranging and collating

• Array of technologies for stack feeding solutions

MGS is dedicated to delivering successful projects. We are experts in OEM equipment integration, enabling us to be the single source for your total solution.

At MGS, full-time PMP certified project managers partner with you to deliver your project on time and on budget. We fully support all OEM equipment on your line, including engineering, validation, a single source FAT, installation, technical service and operator training.

Our goal is an exceptional customer experience. Don't worry about coordinating multiple suppliers and schedules - let MGS manage your product and deliver a total solution.

The CT Platform is a new common platform for all MGS cartoners, incorporating several OEE enhancing features.

• Compact footprint

• Balcony Design – great visual sightlines, easy access to all parts of the machine for maintenance and end of batch cleanout

• Advanced carton pre-break opens the most difficult cartons

• Validated changeover – carton size changeover in less than 10 minutes

• Printing and Inspection inside the cartoner

• Separate high & low voltage enclosures -Enables quick and safe electrical access

• Optional Illumaguard® available

When a machine experiences a fault, it is vital that the operator is able to quickly find and fix the issue. This can be difficult and time consuming on a large, complex line.

The patent-pending Illumaguard® system alerts operators to machine faults by lighting up the specific guard door panel requiring attention. The operator wastes no time locating the problem – which means your machine is up and running faster, increasing your OEE!

The Illumaguard® system features doors made of Acrylite LED®

• Transmits light

• Superior impact strength

• Noise barrier

• High optical quality

Do you want more information?