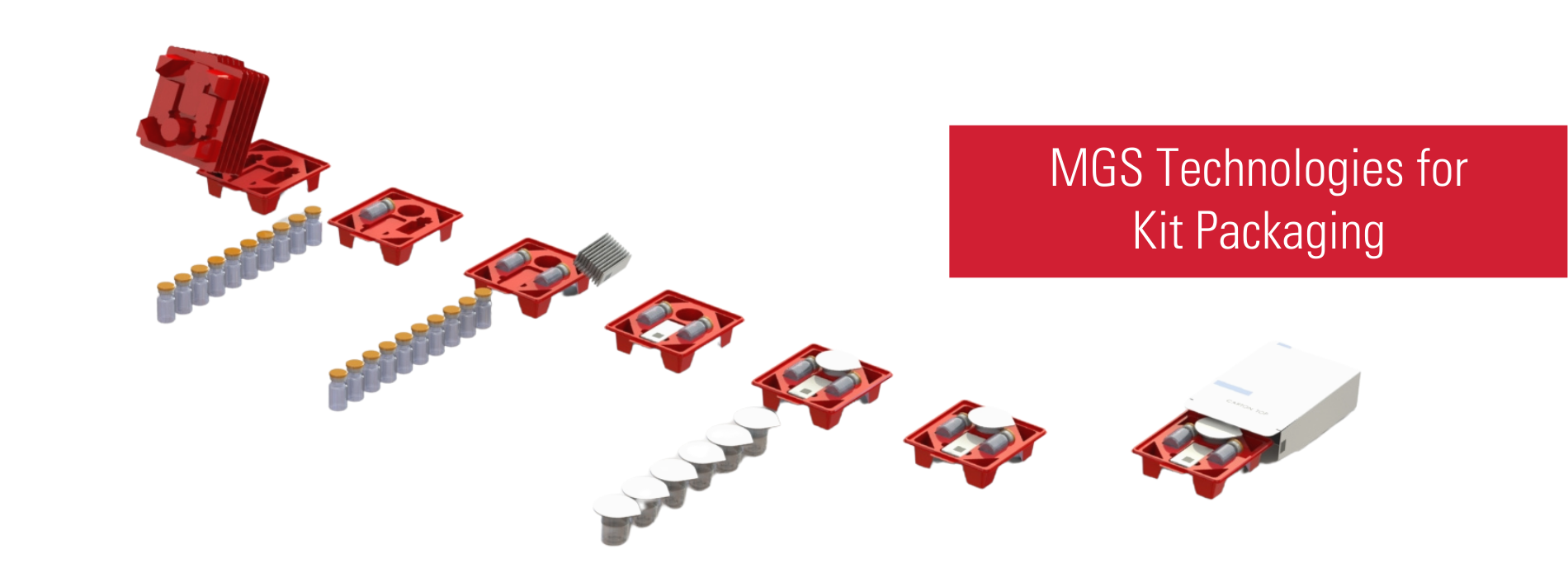

MGS Technologies for Kit Packaging

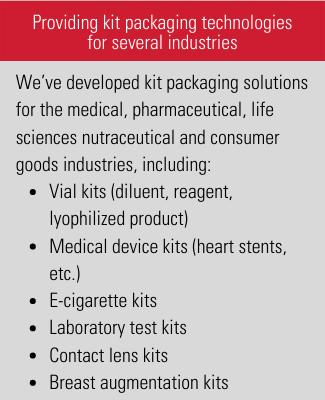

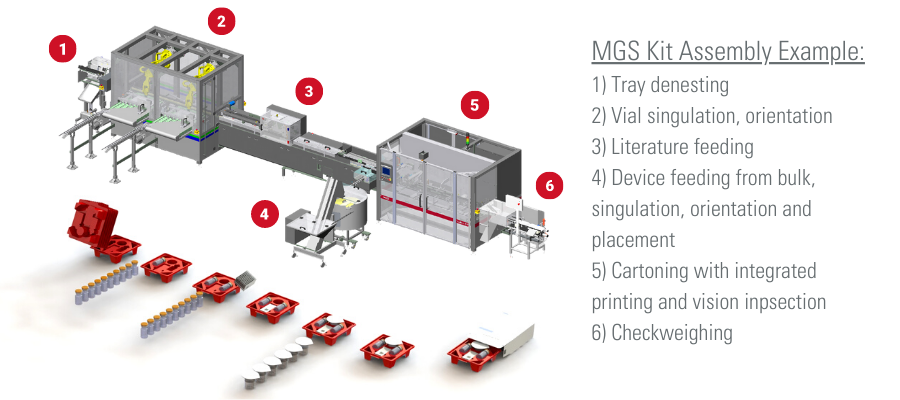

Assembling kit packages involves several types of technology such as tray, literature and bulk feeding, labeling, vision verification, cartoning and case packing. For the pharmaceutical, medical device and nutraceutical industries, the packaging design, testing and validation process can be complex and time consuming. This can create significant challenges for new product launches. Manufacturers need a partner with the expertise to create flexible solutions to help them easily add new products to meet demand.

Solutions that are flexible and scalable

Whether you require a top-load or horizontal platform, we offer the flexibility to assemble kits into whatever format you need. From piecemeal to fully automated, we scale our automation solutions to meet your current needs — and grow with you.

Product handling innovations to fit your needs

Bulk Feeding

MGS offers three types of feeding to help you singulate and orient product at a lower cost and higher volume, when compared to robotic feeding:

- Centrifugal: Offers simple design and robust tooling for efficient product feeding.

- Vibratory: Custom tooling to singulate and orient complex components at high speeds. 316 stainless steel construction available for demanding hygienic requirements.

- VersaSort system: Counterflowing conveyors gently singulate and orient product.

Robotics

MGS has extensive robotic integration experience, including vision-guided applications. For complex product transfers, robotics offer great flexibility in both processes and line construction. In addition to allowing manufacturers to reallocate vital labor resources, robots provide:

- Reduced human error

- Faster and more accurate placement

- Improved safety and ergonomics

- A hygienic environment

We also offer collaborative robot solutions when you need robots to work safely in close proximity to humans on the line, saving floor space normally needed for guarding.

Tray Feeding/Handling

Many kits use trays or carriers to place and organize product in its final package. We offer a variety of tray-feeding machines that can denest stacked trays and place them accurately online for downstream processes. We can also accommodate work-in-progress (WIP) products from several sources.

Vast experience with track and trace

Need to validate your line to prevent counterfeits and protect consumer safety? Our knowledge and experience with serialization systems for verification means you can be confident everything on your line — from literature to label sheets and carton lot/date codes — is accurate.

Expert assistance in validation

As an experienced industry expert, you can rely on us to assist you in your commissioning efforts. Our Commissioning Documentation Package sets industry standards and greatly reduces your workload during validation, helping you get to full production as quickly as possible.

If you have questions on the technologies that make kit packaging successful, reach out to us at info@mgsmachine.com or request more information below.