LEADERS IN SMALL-CALIBER AMMUNITION PACKAGING MACHINERY

WE'VE PROVIDED EQUIPMENT TO THE HIGHEST-VOLUME PRODUCERS OF AMMUNITION IN THE U.S., BOTH FOR GOVERNMENT AND COMMERCIAL SUPPLIERS

Join MGS at SHOT Show 2026 this January 19th to January 20th at booth #52405 during the Supplier Showcase.

As a leader in ammunition packaging automation, MGS has proven expertise in both high-speed, bulk ammunition packaging as well as expanded small batch ammunition capabilities.

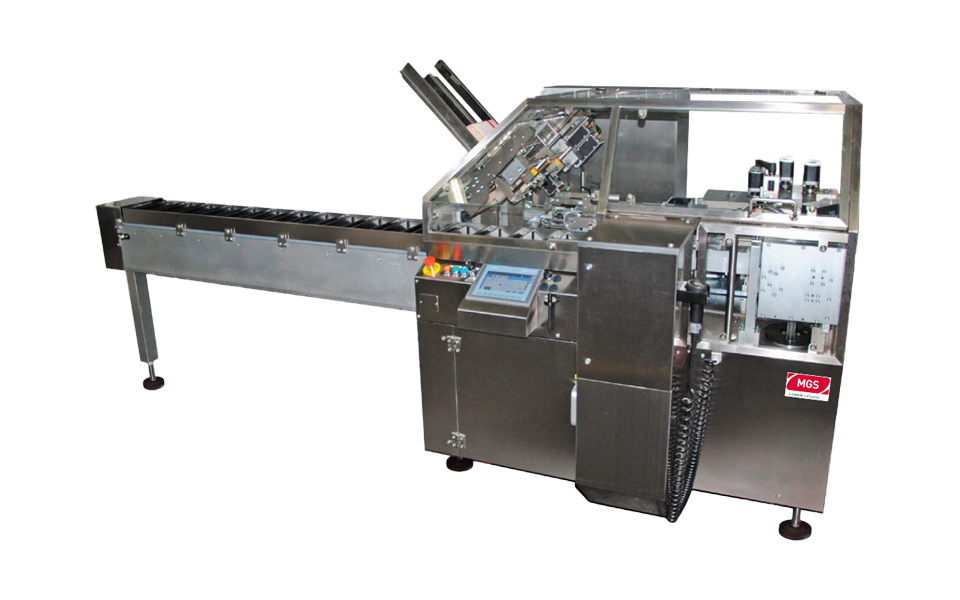

Stop by our booth to discuss our many solutions, such as the compact and cost-efficient KP600 cartoner, our newest ammunition packaging solution. The KP600 can run up to 30 cartons a minute with manual, semi-automatic, or fully automatic loading capabilities and changeovers that take less than 10 minutes.

DDTC registered, MGS is an ITAR manufacturer and exporter. We operate with a full understanding of stringent market regulations and compliance requirements so we can create solutions tailored to ammunition industry needs.

Register for SHOT Show Supplier Showcase here.

Meet us

SHOT Show, 19 to 20 January 2026.

The Venetian Expo 5th Floor Palazzo Ballroom

Booth #52405

MGS operates in full compliance with export control regulations governing defense-related technologies and has implemented comprehensive measures to meet all applicable ITAR requirements.

• Rates up to 30 cartons per minute

• Tool-free changeovers in under 10 minutes

• Entry-level base price

• Easy configuration of all tuck cartons - straight or reverse

• Packaging configuration set up data registered in recipe

• Assisted changeovers via intuitive touchscreen HMI

• Easy-access to all adjustment and maintenance points

• Bulk fed tray loading modules available for complete automation

Our innovative methodologies take ammunition from bulk and singulate and orient it before it's placed into a carton or tray.

VersaSort™ Bulk Feeder

Our feeder features refined cartridge singulation, orientation and grouping techniques to deliver a controlled product stream. This gentle bulk-handling system minimizes recirculation, resulting in ammunition that’s as close as possible to its manufactured quality.

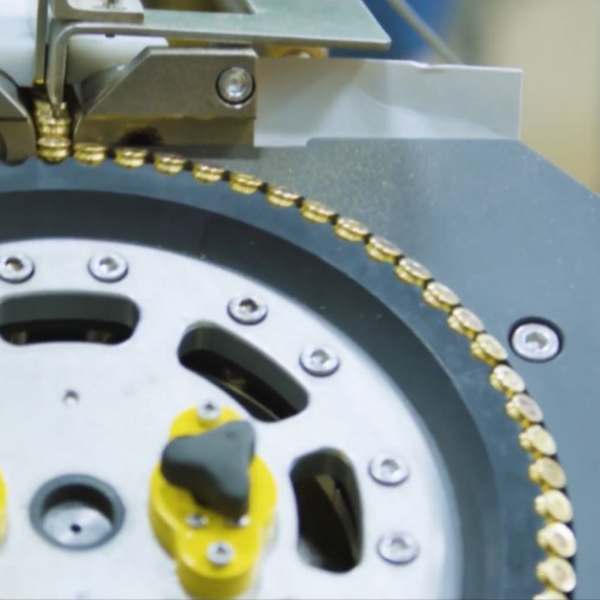

Cartridge Singulation Miter Starwheel and Chicane Cartridge Buffer

Our patented new technology is a connector between the VersaSort and the cartoner, serving two important functions: consistently and positively reorienting cartridges and creating a product buffer to handle bulk feed variability.

With Accuracy and Ensuring Product Integrity

Vision camera integration

We have vision systems available to confirm the presence of primers and projectiles. Incomplete rounds are ejected and verified to ensure customer satisfaction. We also have operator inspection stations with ergonomic seating as well as lighting and mirrors that allow for thorough cartridge quality inspection by your trained technicians.

Cartoning, case packing and palletizing

Our cartoner portfolio features a wide range of offerings, from low-speed, intermittent motion units through high-speed, continuous motion configurations. We also offer a fully automatic case packer as well as manual case packout stations, inkjet and laser carton and case printing, case labeling and several palletizer options to meet your needs.

SPEED. ACCURACY. EFFICIENCY.

Let MGS solve your toughest challenges. We'll deliver a comprehensive packaging solution to meet your specific needs.